Metal & CNC

In the CNC and metal industry, precision and reliability are of the utmost importance. And leveraging production efficiency, operational monitoring, and predictive maintenance on machinery is essential. These tools streamline processes, provide real-time insights, and help prevent costly breakdowns.

Data driven decisions for a better production

Realtime data from your machines can improve productivity, reduce downtime, and ensure consistent, high-quality metal production. Better data also enables better decision-making, and will help you prevent expensive breakdowns and utilize the full potential of your production.

The applications Trendlog offer

Realtime Production

Realtime Production offers a full real-time production overview, providing insights into productivity, downtime reasons, and it enables optimizing OEE by eliminating bottlenecks.

Maintenance Planner

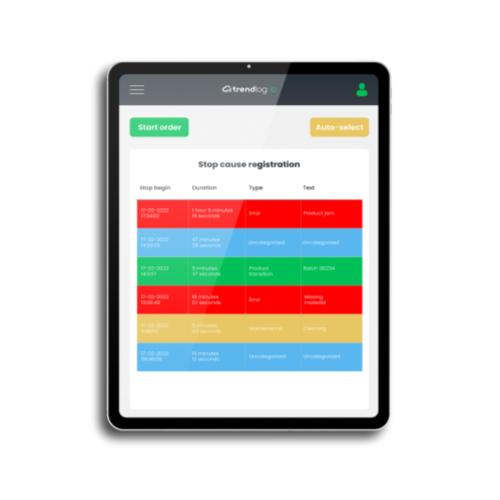

Stop causes

Minimize production costs by identifying the causes of downtime. Operators use tablets to record issues, aiding documentation of bottlenecks and preventing future challenges.

Quality reporting

Energy Meter

Enhance your insight into resource usage with Energy Meter. Track electricity, water, heat, gas, and more to optimize consumption, identify waste, and save costs effectively.

Freemium

Want to try it out? With our Freemium versions, you can try some of our solutions for free, and you’ll have access to graphs, reports and our Maintenance Planner.

Why Trendlog?

Revolutionize production planning, optimization and control. A tailored solution empowers you to streamline data collection, analyze key metrics like OEE and energy consumption, identify stop causes and bottlenecks, and implement predictive maintenance for optimized machine performance.

Before

- Manual data collection

- Too much downtime

- Limited insights equal risky decisions

- Missed optimization opportunities

- Higher rate of production errors and quality issues

- Undetected resource waste

After

- Automatic data collection

- Realtime data insights

- Centralised acccess to information

- Reduced number of errors

- Improved production efficiency

- Well-informed decision making

- Reduced operating and maintenance costs

- Identifiyng bottlenecks and quality issues

- Optimized resource consumption

Application: Realtime Production

Do you want to know what’s causing you downtime? We can gather real-time data from across your production and give you a comprehensive overview of your production processes. And our Realtime Production application provides you with the insights that can help you make effective improvements on your output and overall efficiency.

Take the first step, reach out to us for a quick demo.

L&P Springs increased their efficiency by 5%

The manufacturer of springs for mattresses, L&P Springs, has been utilizing their data with the Trendlog system to monitor their machine efficiency as well as maintenance needs. Check their story to see what they gained from it.

Become a member of Club Trendlog

You will be receiving the latest news, inspiration, customer cases and much more 1-2 times a month. Subscribe to our newsletter here.

The newsletter is for you, who is interested in learning more about digitalization in your production. We are mainly focused on 5 different industries including:

- Agriculture

- Food and beverages

- Plastic manufacturing

- Metal & CNC

- Packaging