Realtime production & OEE

TrendOEE

Monitor your machines and production LIVE. With TrendOEE, you get a complete overview of efficiency, downtime, and stop causes – all in one place, powered by real-time data.

See how TrendOEE creates insights and results

TrendOEE helps you optimize production through LIVE data and insights into key metrics, stop causes, and shift performance. Watch the video and discover how you can increase efficiency right away.

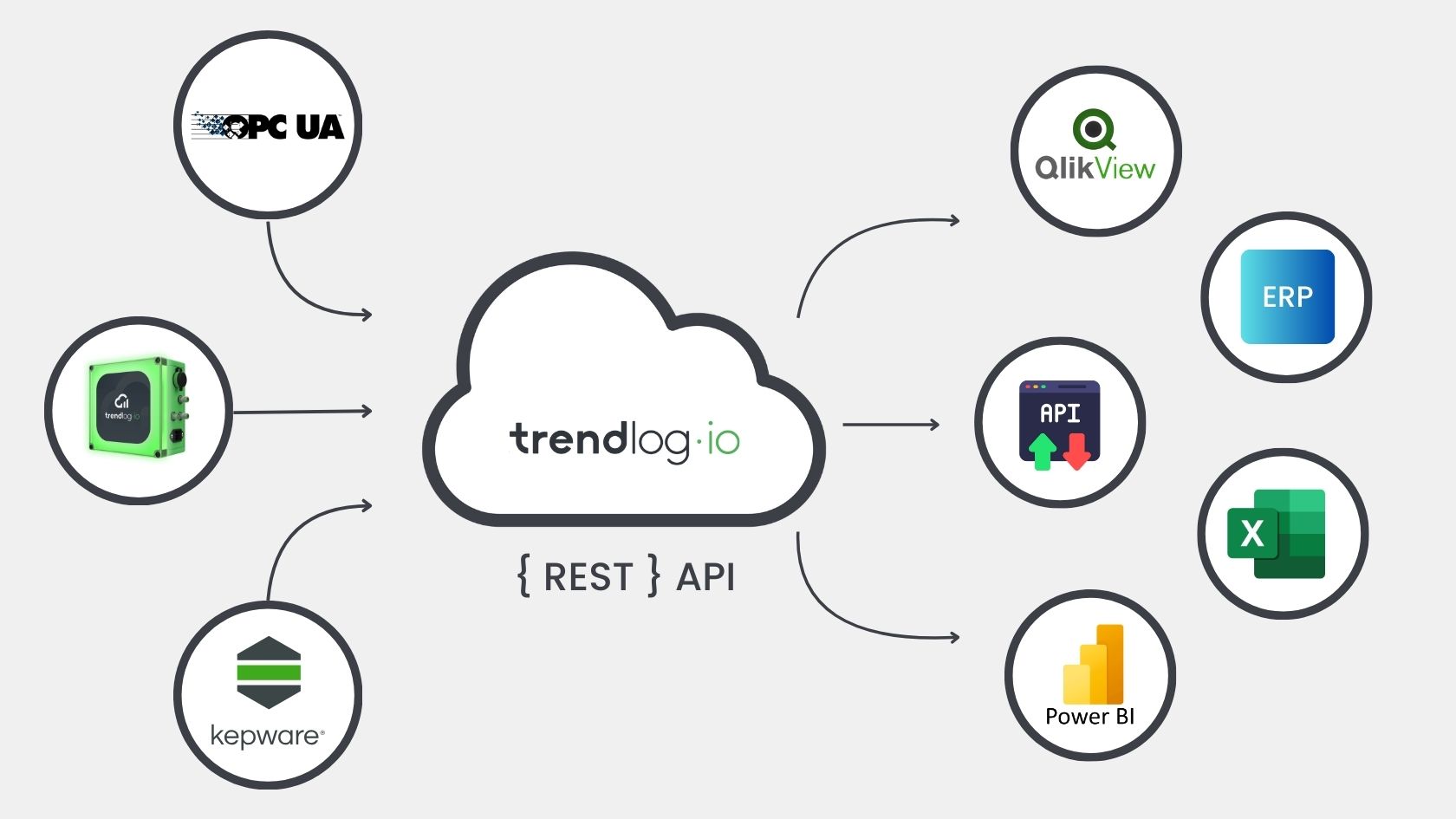

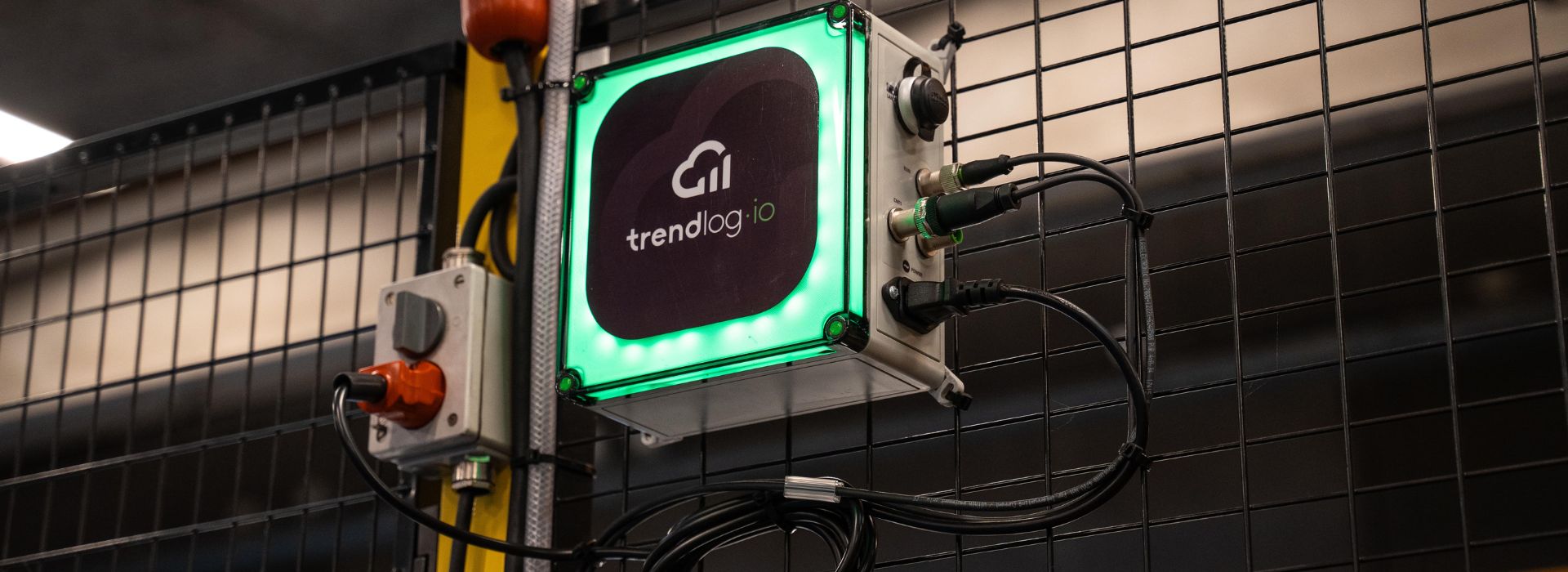

Intelligent data collection

Collecting your data

Capture data from all types of machines and systems – both digital and analog. With our COLLECT boxes and open API, you can integrate ERP, BI, and planning tools to create one unified data foundation.

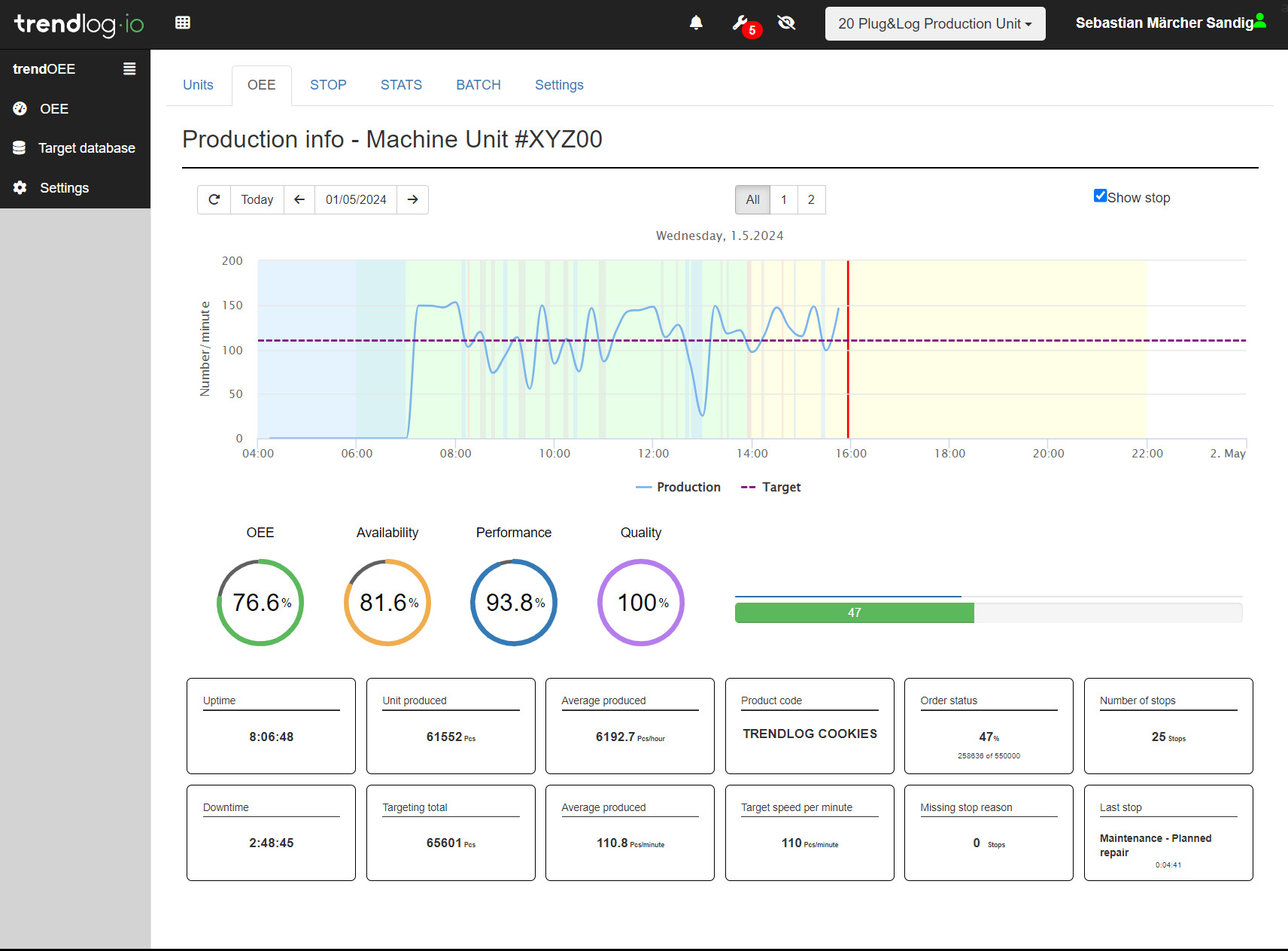

LIVE insights and overview

Monitor performance

Track production in real time. View machine status, output, downtime, waste, and efficiency directly on a single dashboard – enabling faster and better decisions.

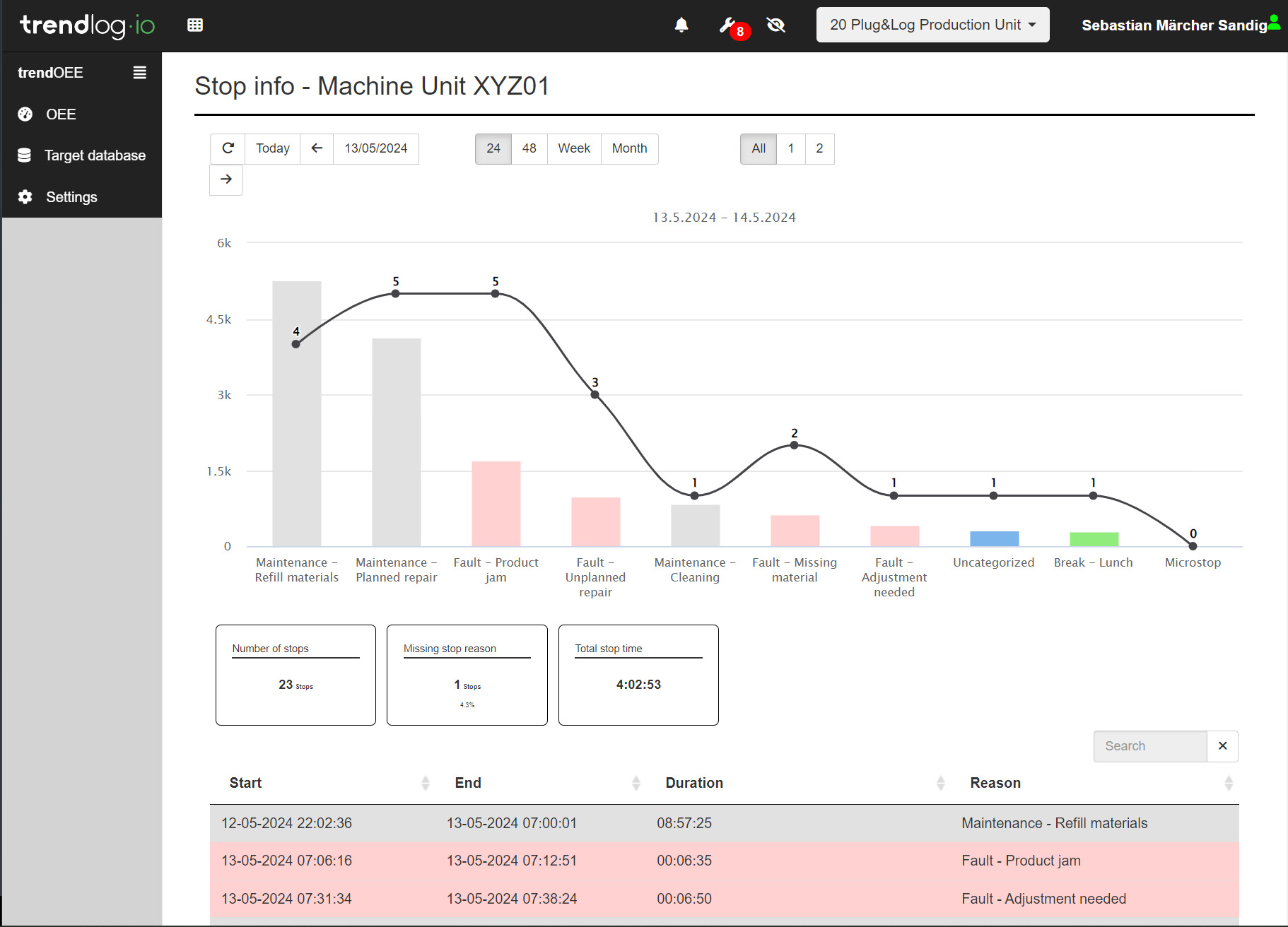

Easy stop cause registration

Know your stop causes

Gain insight into why production is stopping. TrendOEE makes it easy to register and analyze stop causes so you can identify patterns and reduce costly downtime.

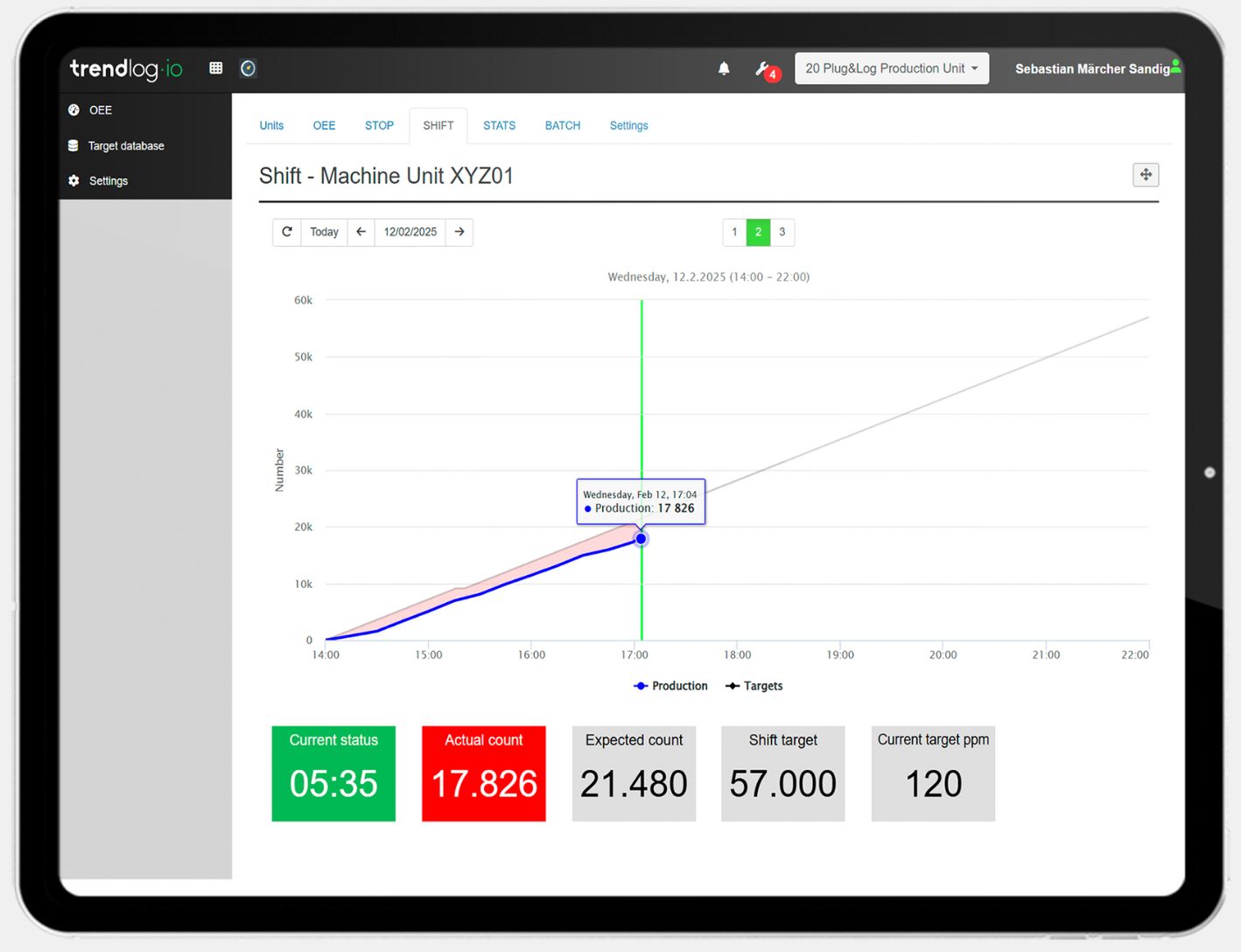

Shift & Production Order Tracking

Smart production management

Compare performance across shifts and gain insight into whether you’re ahead or behind on your production schedule. Keep motivation high and plan more effectively.

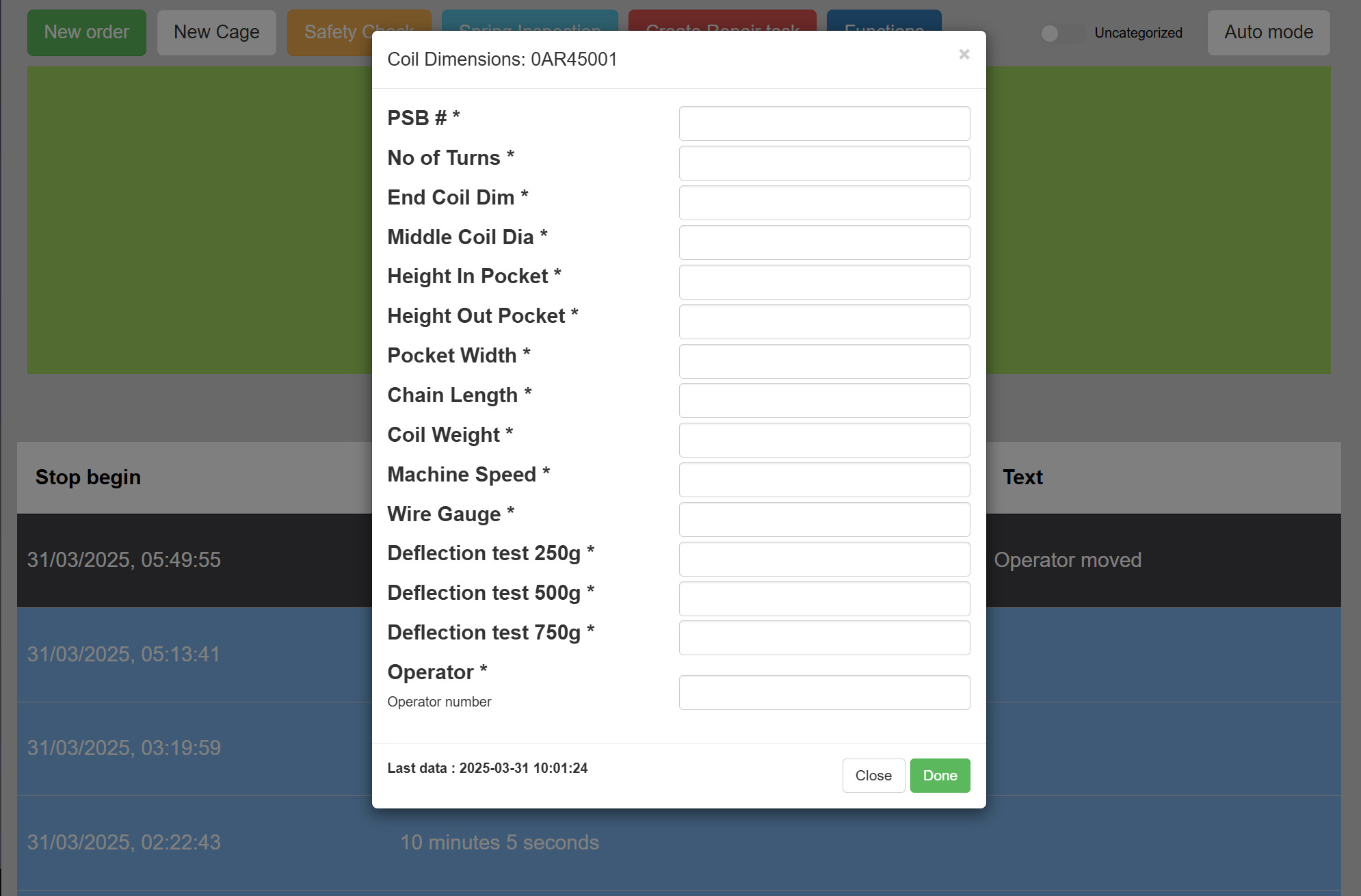

Paperless production with TrendFORMS

Implement digital QA

Replace paper checklists with user-friendly digital forms. TrendFORMS makes it easy to log inspections and quality data directly from the shop floor – quickly, accurately, and paper-free.

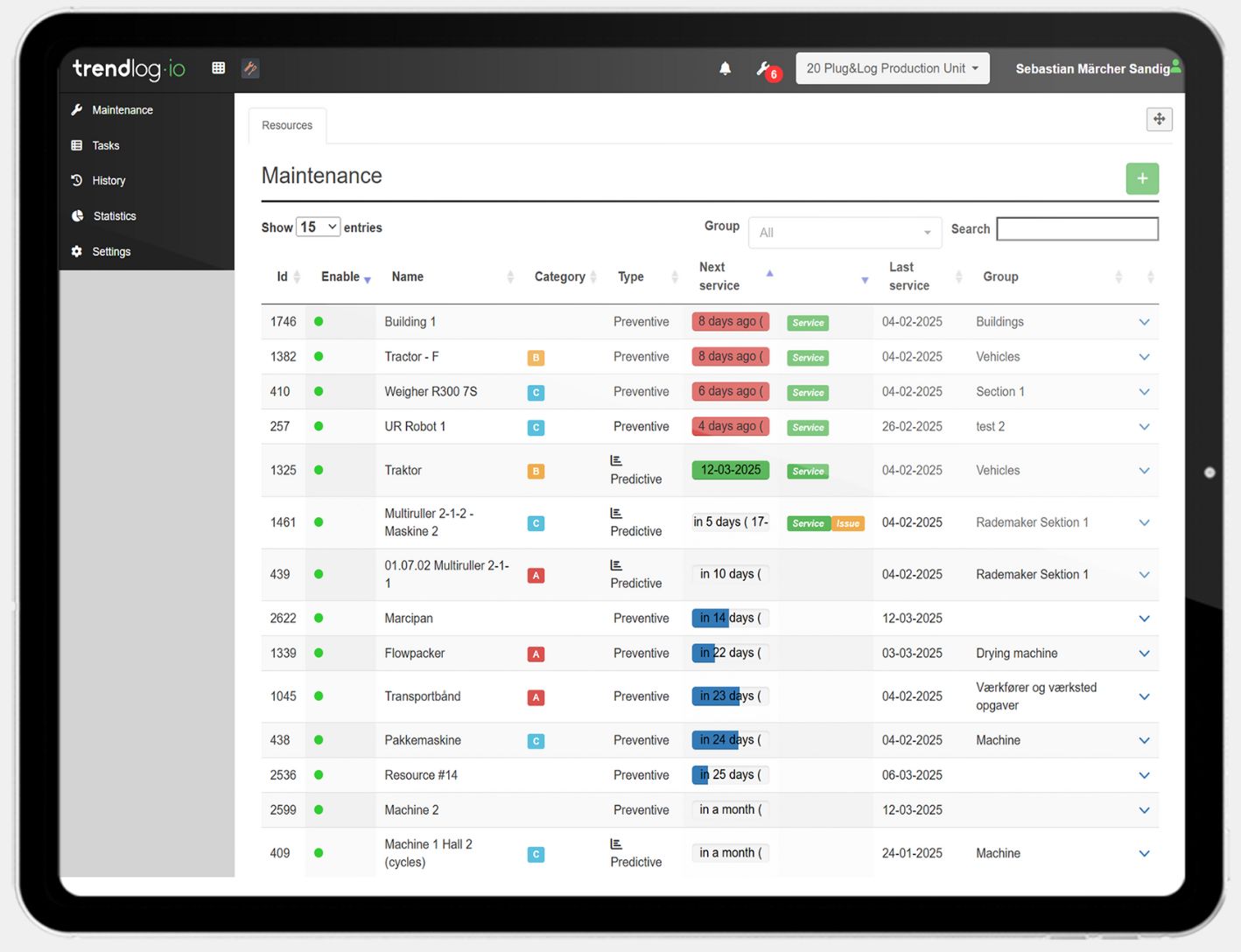

Maintenance Planner

Improve machine maintenance

Connect operational data with maintenance. Plan and automate service tasks, and use actual runtime data to predict and prevent breakdowns.

Easy setup, huge impact.

With our COLLECT boxes and user-friendly platform, you’re up and running quickly. We assist with setup, integration, and training, so you start gaining value from your production data – whether you begin with one machine or your entire line.

CASE: TrendOEE & Maintenance Planner

How LINDAB optimizes their production & maintenance

The story of how a multinational company manages their maintenance across several sites, reducing their cost of operations and increasing their efficiency

What does TrendOEE cost?

TrendOEE is offered as a subscription per production line, allowing you to scale easily and get started quickly. Additional setup and hardware costs may apply. Contact us for a customized quote tailored to your production setup.

PRICE PER LINE / MONTH

€35

FOR UP TO 10 PRODCTION LINES

Included in the subscription:

- LIVE OEE and KPI’s

- Downtime and stop cause tracking

- Shift and production order tracking

- Unlimited users and dashboards

- Mobile- and tablet-friendly interface

- Fast and reliable support & service

Frequently Asked Questions

How does TrendOEE provide real-time insight into production?

TrendOEE collects live data from your machines and shows performance, downtime, output, and waste in one dashboard – accessible on any screen, tablet, or PC.

How are downtime and stoppages registered?

Downtime can be automatically triggered from machine signals or logged manually by operators using the TrendSTOP app. This provides clear, accurate insight into root causes.

Can we compare performance between shifts or teams?

Yes – TrendOEE includes shift tracking, so you can monitor how different teams perform and improve accountability and communication between shifts.

Can we integrate production orders from our ERP system?

Yes – TrendOEE can be integrated with your ERP via API or manual entry. You can also use tablets or barcode scanners to register orders directly on the floor.

Can we see if we’re ahead or behind schedule in real-time?

Yes – TrendOEE shows live progress against each production order, so you can see deviations and take action instantly.

How quickly can we get started with OEE tracking?

You can start with just one production line and expand as needed. Setup is fast, and we support you with everything from hardware to onboarding.

Ready to take control of your production?

Experience how real-time data and insights into stop causes, waste, and efficiency can make a real difference for your production.