Energy Meters

With the production of goods often comes energy-intensive operations. Trendlog offers several options to track energy consumption so you can make a difference for your company.

Reduce your consumption

Monitoring the consumption of energy and other resources from machines in a factory can contribute to reducing consumption in several ways.

Real-time data on energy and resource consumption provides valuable insights for optimizing production processes.

This insight allows you to address inefficiencies and optimize processes for better resource utilization.

Our Energy & Consumption Meters

Take a look at a selected overview of sensors and meters used to monitor the consumption from machines and factories. Contact us to find the best solution for you.

Shelly Energy Meter

- Measure energy consumption from machines, equipment or whole factories

- DIN rail mounted

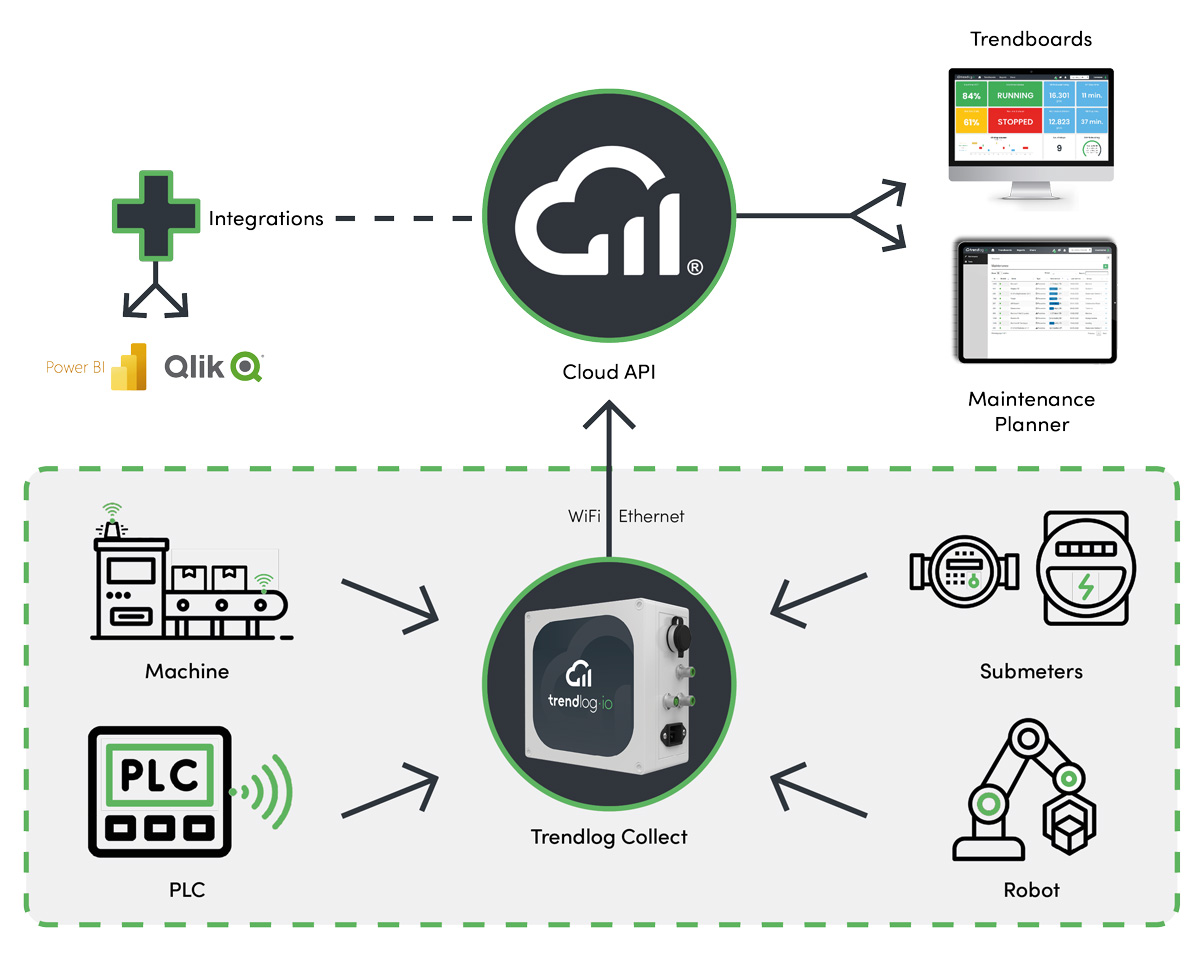

- Connects to gateway to forward data to Trendlog Cloud

- WiFi or Ethernet connectivity

- H x W x D: 94 x 19 x 69mm

Schneider Electric Energy Meters

- Measure energy consumption from machines, equipment or whole factories

- Several models available

- DIN rail mounted

- Connects to gateway to forward data to Trendlog Cloud

- Ethernet connectivity

Moxa I/O Module

- Measure the consumption of energy, water, gas etc. with an I/O-module from Moxa

- DIN rail mounted

- Connects to the submeters and forwards the data via a Data Forwarder to Trendlog Cloud

- Ethernet connectivity

Get started

Our partners make sure that the integration experience is easy and smooth, so you won’t need to worry about that! And with a plug-and-play solution, tailored to your needs, you will empower your factory to achieve new levels of efficiency, reduce costs, and increase profitability.

What WE will do:

- Technology selection – We supply the data collectors and sensors that fit your needs

- Technical plan – We figure out which signals we need from the machine or equipment

- Integration – We coordinate the integration of the system with our partners or your technicians

- Data storage & security – We ensure that your data is collected and stored safely

- Data visualization – We make sure that you can access your data from Day 1

What YOU will do:

- Choose your interests – Do you want to monitor uptime, OEE, energy or maintenance?

- Include personnel – Participate in training sessions and explore the possibilities

- Gain new insights – Start mapping bottlenecks, stop causes, waste areas, and other inefficiencies

- Elevate your production – Explore the potentials of your production & document all improvements

Become a member of Club Trendlog

You will be receiving the latest news, inspiration, customer cases and much more 1-2 times a month. Subscribe to our newsletter here.

The newsletter is for you, who is interested in learning more about digitalization in your production. We are mainly focused on 5 different industries including:

- Agriculture

- Food and beverages

- Plastic manufacturing

- Metal & CNC

- Packaging