IIoT Devices

With easily accessible data, you can make a difference for your company. And with the right data, better decisions follow.

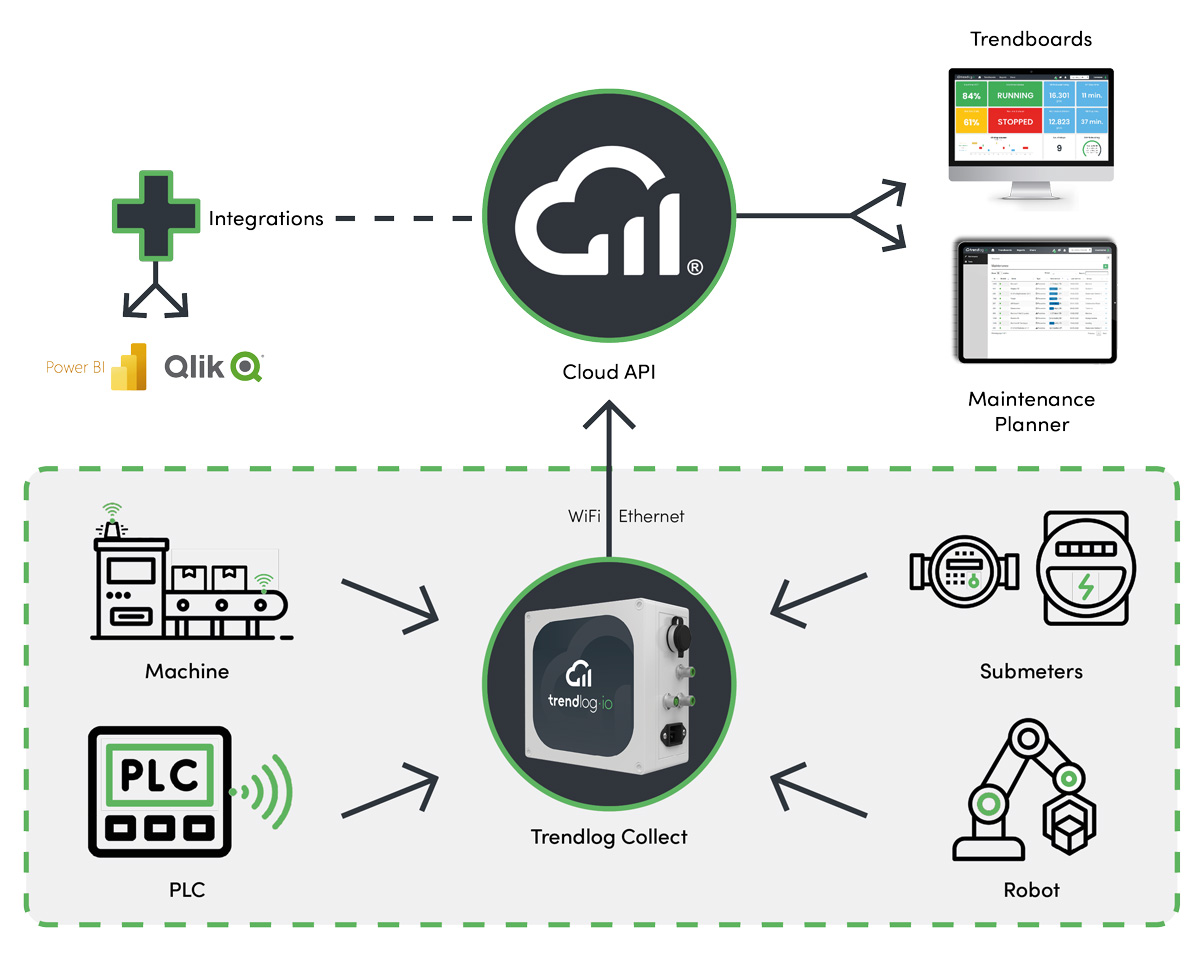

A Plug & Play solution

Trendlog can offer various options for collecting important information from the factory, allowing you to monitor your production processes efficiently.

When you need to gather information from production machinery, robots, or sensors, we have models for both the simple and more advanced installations.

Our IIoT Device Options

Take a look at a selected overview of the data collectors mostly used in applications for collecting and monitoring operational data from machines and production equipment.

TL Collect UNO

- Retrofitted data collector

- Plug & Play integration

- Acts as data gateway to Trendlog Cloud

- Saves time on wiring costs

- Can connect up to 8 machines digitally for data collection

- H x W x D: 90 x 180 x 182 mm

TL Data Forwarder

- Advanced Option

- DIN compatible

- VPN accessibility

- Acts as data gateway to Trendlog Cloud

- Can connect up to 8 machines or more digitally

- H x W x D: 96 x 22.5 x 110.5 mm

TL Extenders

- I/O connection between the extenders and to a local data gateway

- DIN compatible

- Connects to machines with digital or analog input

- Supports a series of commonly used communication protocols

- Works with Collect UNO & Data Forwarder

If you want to dive into more advanced settings, then please visit our Trendlog Academy for guidance and inspiration.

Get started

Our partners make sure that the integration experience is easy and smooth, so you won’t need to worry about that! And with a plug-and-play solution, tailored to your needs, you will empower your factory to achieve new levels of efficiency, reduce costs, and increase profitability

What WE will do:

- Technology selection – We supply the data collectors and sensors that fit your needs

- Technical plan – We figure out which signals we need from the machine or equipment

- Integration – We coordinate the integration of the system with our partners or your technicians

- Data storage & security – We ensure that your data is collected and stored safely

- Data visualization – We make sure that you can access your data from Day 1

What YOU will do:

- Choose your interests – Do you want to monitor uptime, OEE, energy or maintenance?

- Include personnel – Participate in training sessions and explore the possibilities

- Gain new insights – Start mapping bottlenecks, stop causes, waste areas, and other inefficiencies

- Elevate your production – Explore the potentials of your production & document all improvements

Frequently Asked Questions

What’s the difference between COLLECT, Forwarder, and Extenders?

COLLECT is our main plug & play edge device. Forwarder is a built-in version for control cabinets, and Extenders expand the number of inputs for larger setups.

How many machines or meters can one device support?

A single COLLECT unit can typically connect up to 8 machines or meters. Using Extenders, you can scale up to dozens of inputs from one gateway.

What communication methods are available?

Devices support Ethernet, WiFi, and optional 4G connectivity – making them easy to install in almost any factory environment.

Can the devices work with older machines?

Yes – the hardware is designed to retrofit legacy equipment by tapping into analog or digital signals, making any machine “smart”.

Is Trendlog hardware secure and cloud-ready?

Yes – all devices use encrypted communication and are fully compatible with Trendlog CLOUD. Setup is quick and requires minimal IT involvement.

Ready to connect your production?

Want to see how COLLECT can be connected to your machines and meters? Book a demo or get a no-obligation quote on a setup tailored to your production.